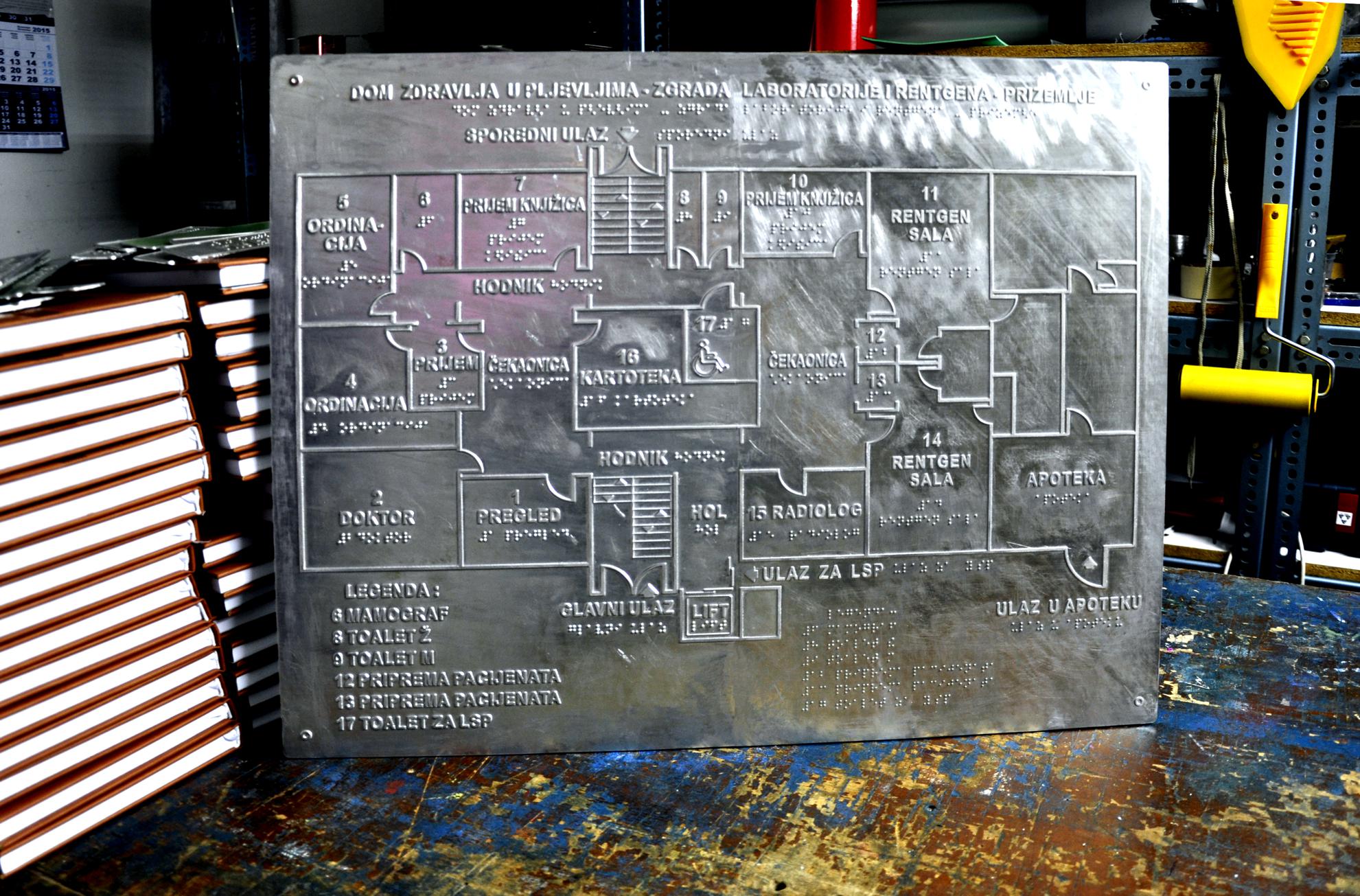

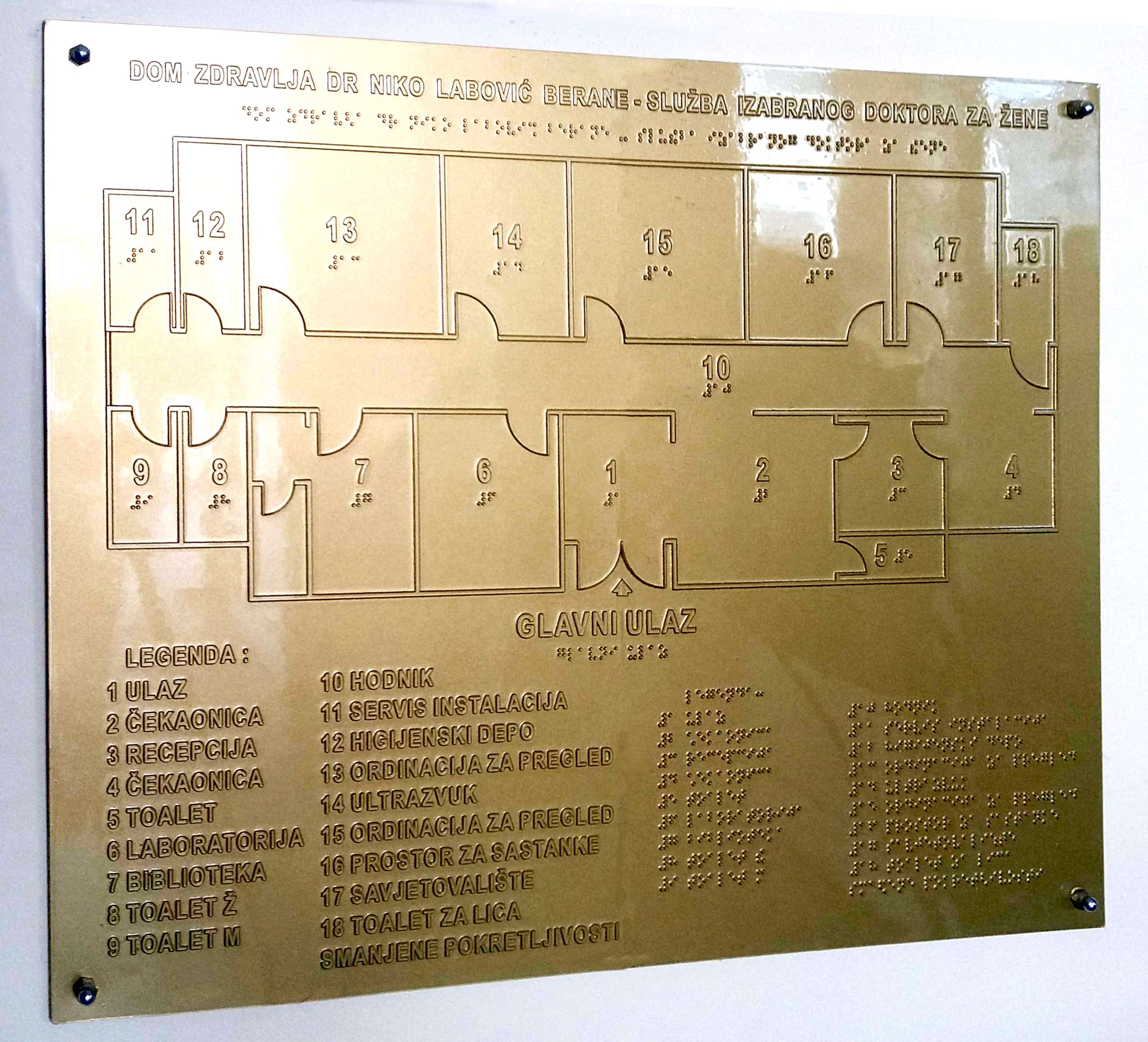

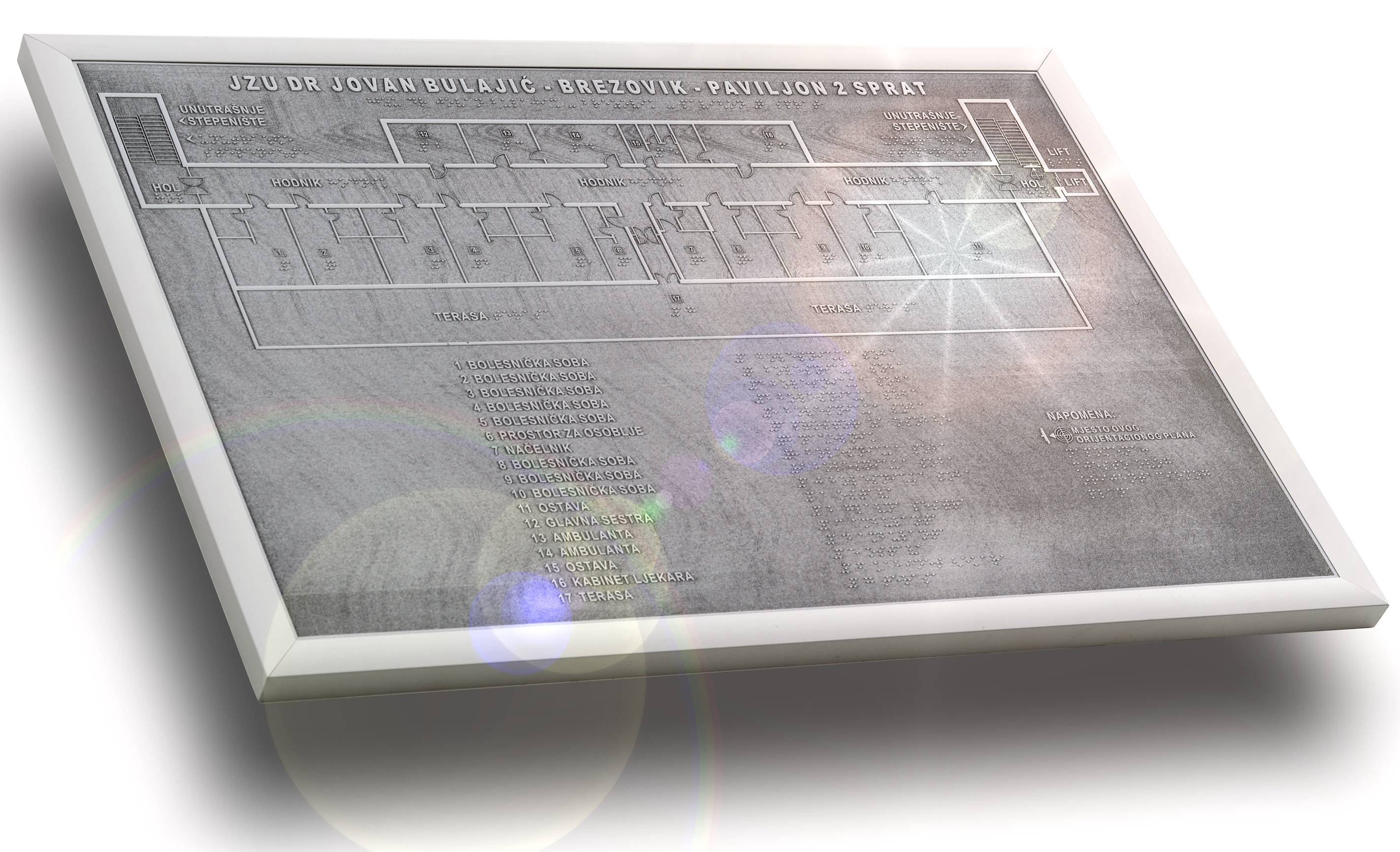

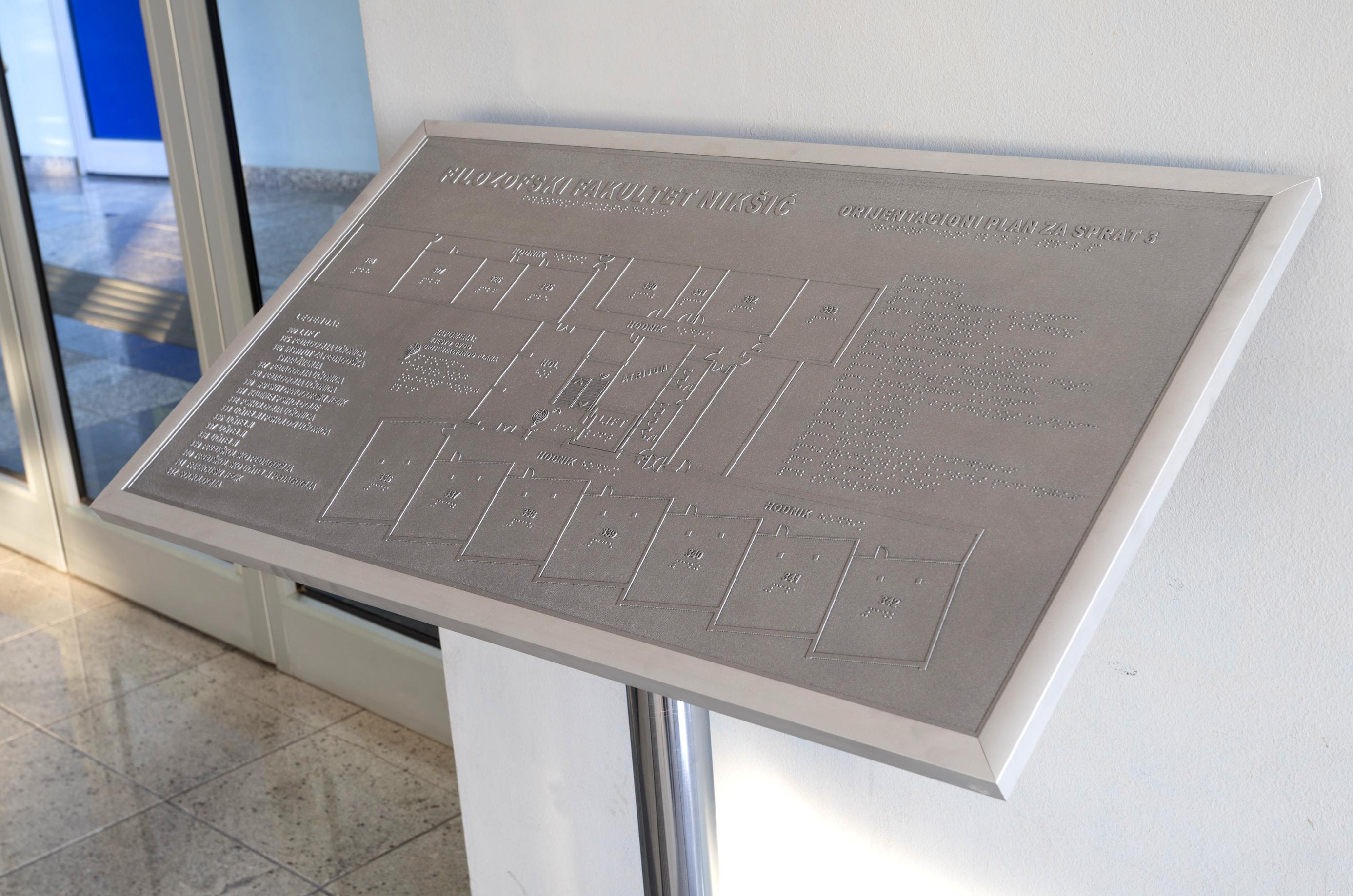

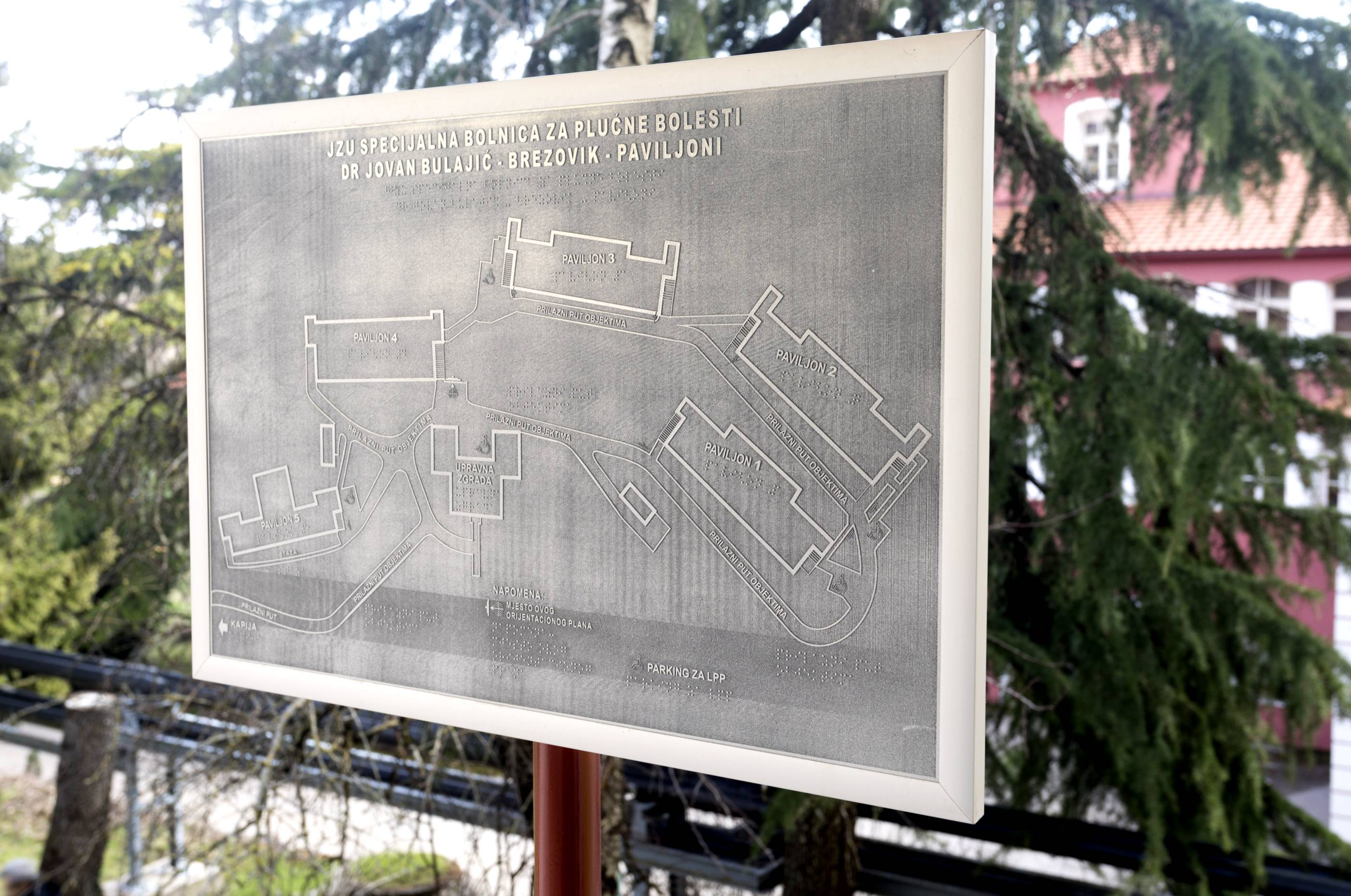

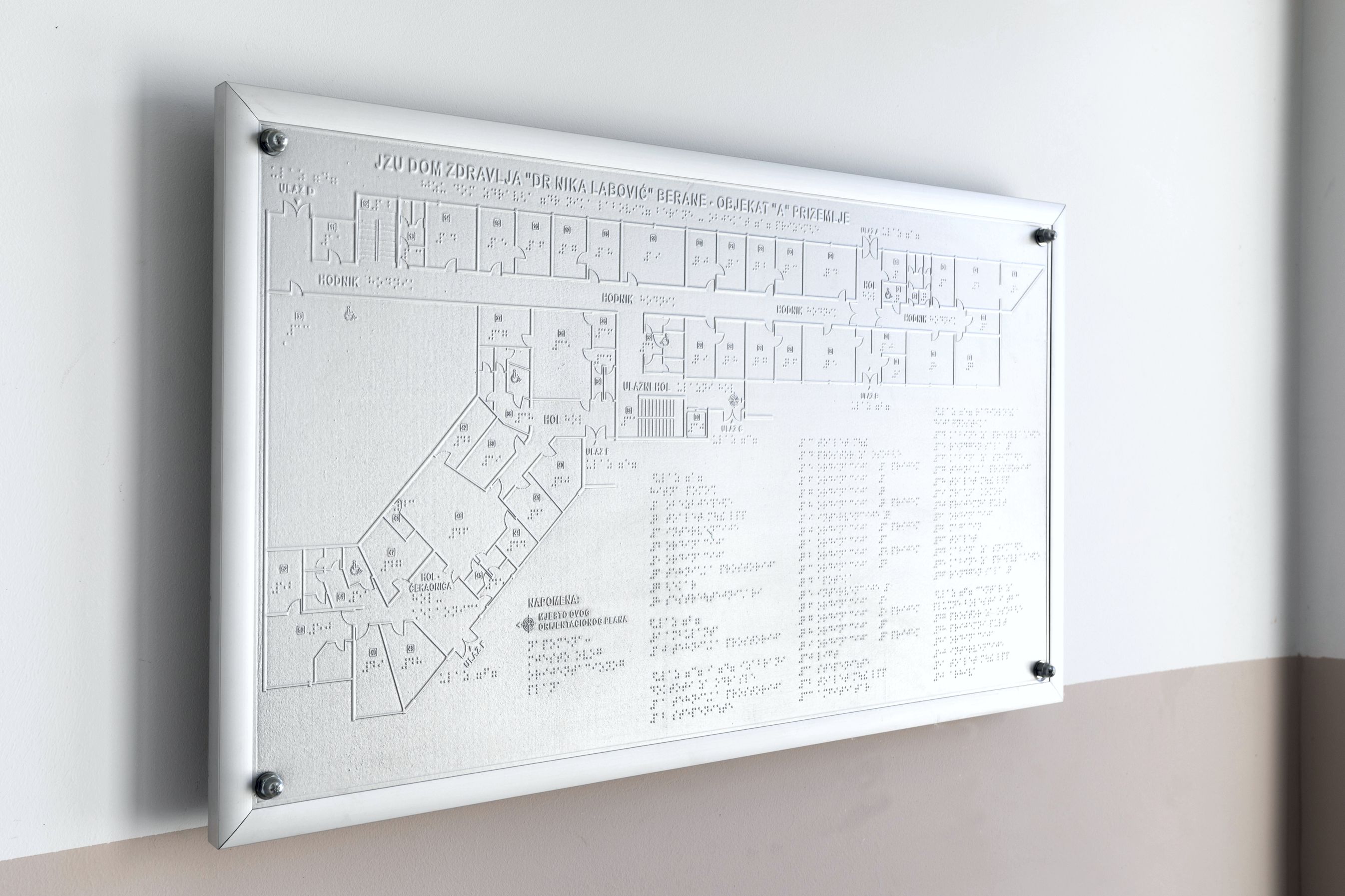

Tactile Orientation plans with Braille letter

Tactile Orientation plans can be made from metal or plastic plates with the engraved orientation plan of rooms and names for the purpose of rooms with classical and Braille letters. The engraved plates have a raw color of the metal surface and as such they get a dark patina oxidation during time, and the plastic plates are black. For this reason, the plates are subsequently lacquered with two-component high-quality lacquers (silver, gold, white ...) depending on the interior, and can be gloss or matt surfaces. This way designed and processed Orijentation plans meet very high aesthetic standards, as well as the complete information function for blind, sand blind and normal vision persons.

Usually format is B2, approximately 70x50cm or as needed ...

Provide information about the layout of rooms for a particular floor of the building, or information in relation to a complete object. This way designed tactile door signs with the Braille letter are ergonomically adapted for finger exploitation by touching and so on. They are very stable and steady, in normal use, they cannot be weared or damaged, without limited shelf life, resistant to all weather conditions, and for metals it should be stated that they are resistant to extreme mechanical influences and are highly representative.

Depending on the designated place for installation, they are delivered with a set of decorative screws and wall mounting parts (vertical installation), with stand for setting in the space: halls, corridors ... (horizontal installation) or on the metal pillar for outdoors (vertical installation).

The process of production is as follows: as the first step, architectural drawings of the base floor, floors, levels... are presented in the electronic format .pdf file. If there are no electronic drawings, an architectural drawing of proportional basis with the numbering and purpose of the premises should be provided.

It approaches to the drawing and development of the 1: 1 film engraving plan and it is submitted for review and approval to the customer in electronic form. According to the approved drawing, the plates are engraved, made, lacquered ...

The above-mentioned production process conditions a longer period of construction, especially for buildings with a lots of floors and entrances ...

They can be cleaned with standard hygiene products that are diluted and rinsed with water without any consequences. During the cleaning, use soft brushes and soft cloths so that the lacquered layer will keep its glaze for as long as possible.